Fluid pipeline series

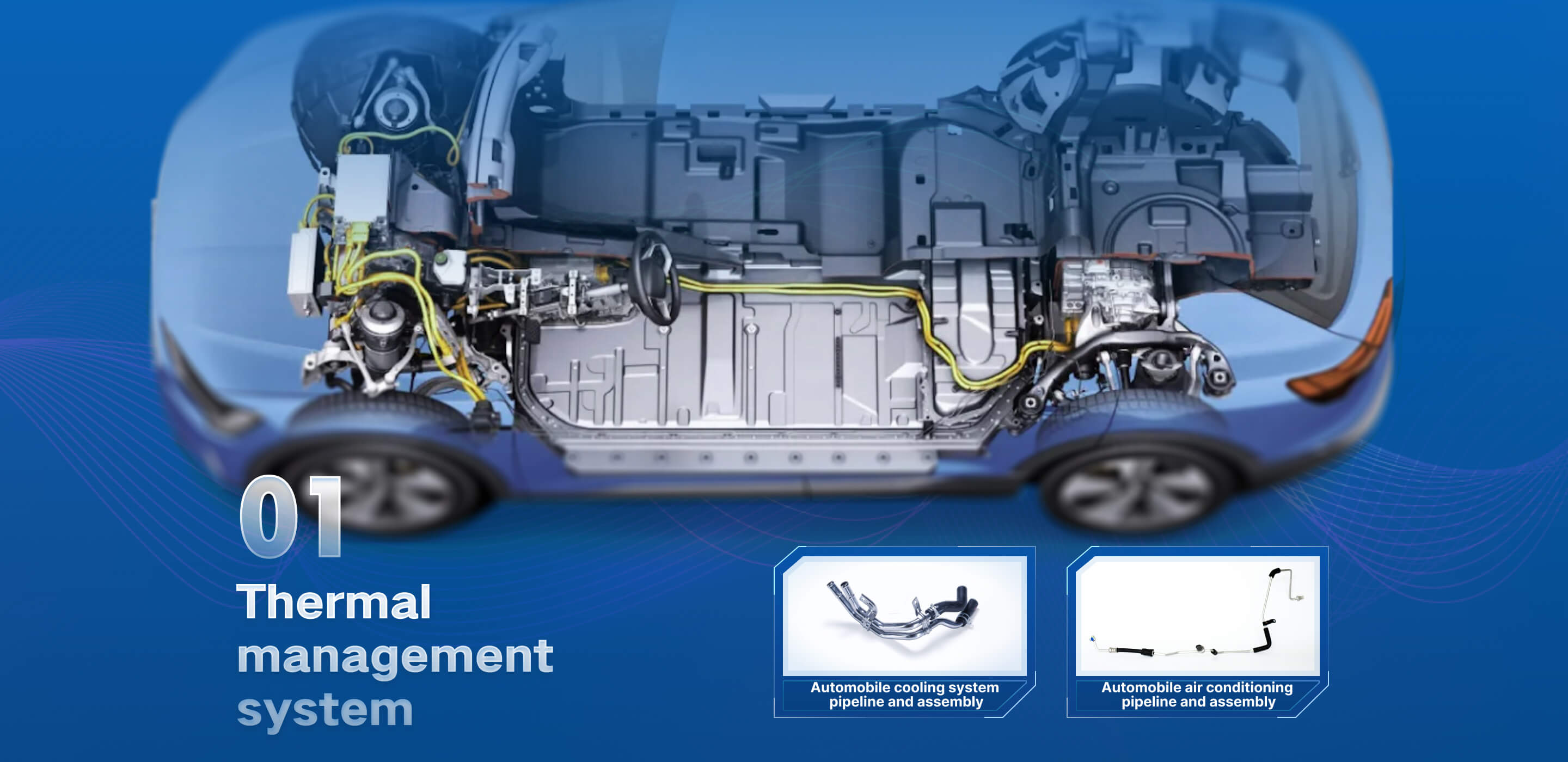

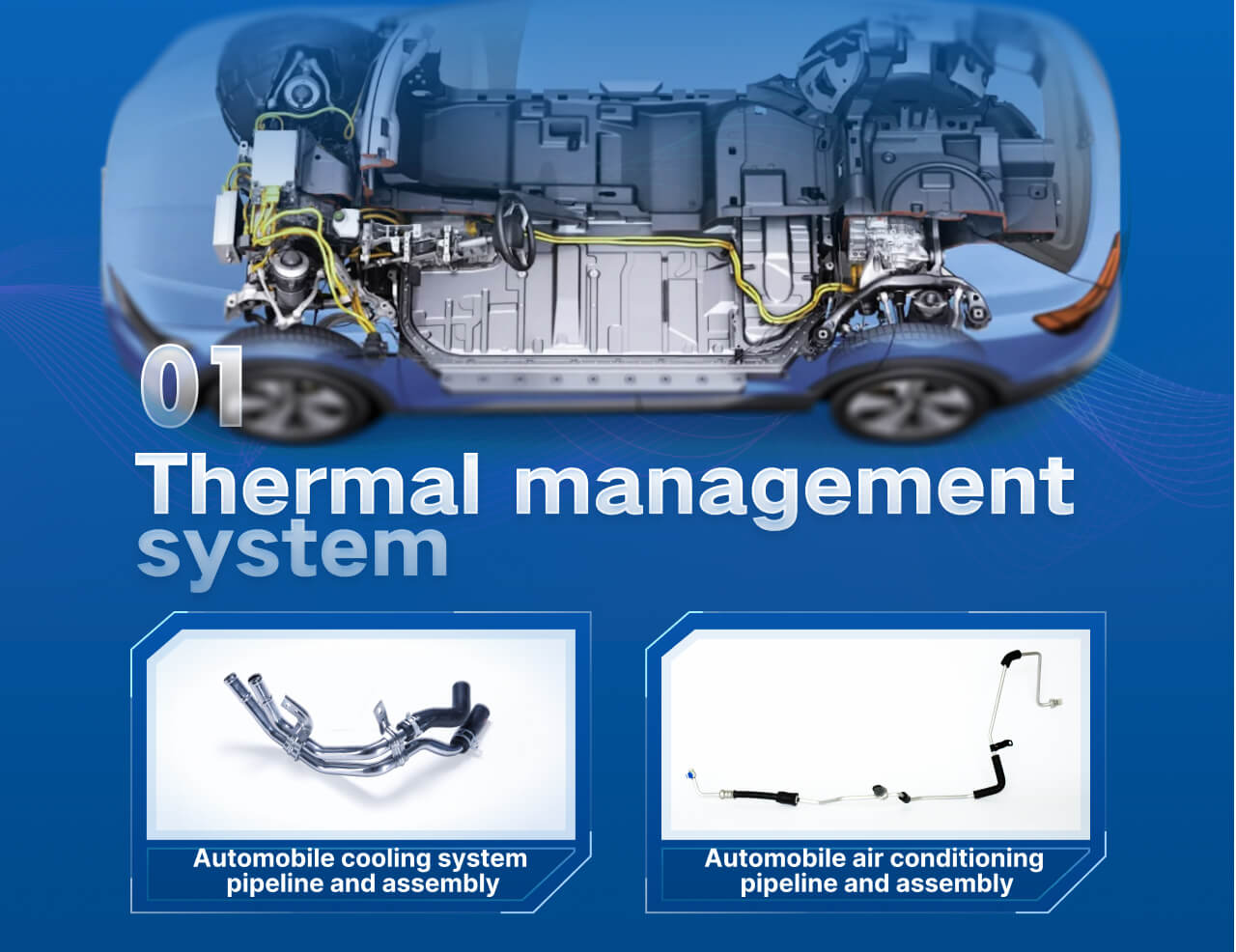

The thermal management system pipeline and assembly The vehicle thermal management system carries and circulates the heat in various areas of the vehicle through the cooling system pipeline and the air conditioning system pipeline, which not only ensures that the engine, power battery, motor and vehicle control system can work at a suitable temperature, but also provides heating and cooling requirements for the passenger compartment, enhancing thedriving comfort.

At the same time, through the heat balance of the whole vehicle, it is also feasible and effective to improve the endurance mileage.

At the same time, through the heat balance of the whole vehicle, it is also feasible and effective to improve the endurance mileage.

Through multi-layer composite extrusion technology, corrugated pipe modular design, integrated intelligent joint design and other related design concepts, automotive cooling system pipelines and assemblies play an important role in reducing product costs, shortening development cycle, and assisting the control strategy of thermal management system.

The nylon material is used as the inner layer of the automobile air conditioning pipeline and assembly, which greatly reduces the permeation of refrigerant; The unique carbon dioxide refrigerant air conditioning pipeline has ultra-high bursting pressure resistant and "zero permeation" product characteristics, and its technology is at the leading level in China.

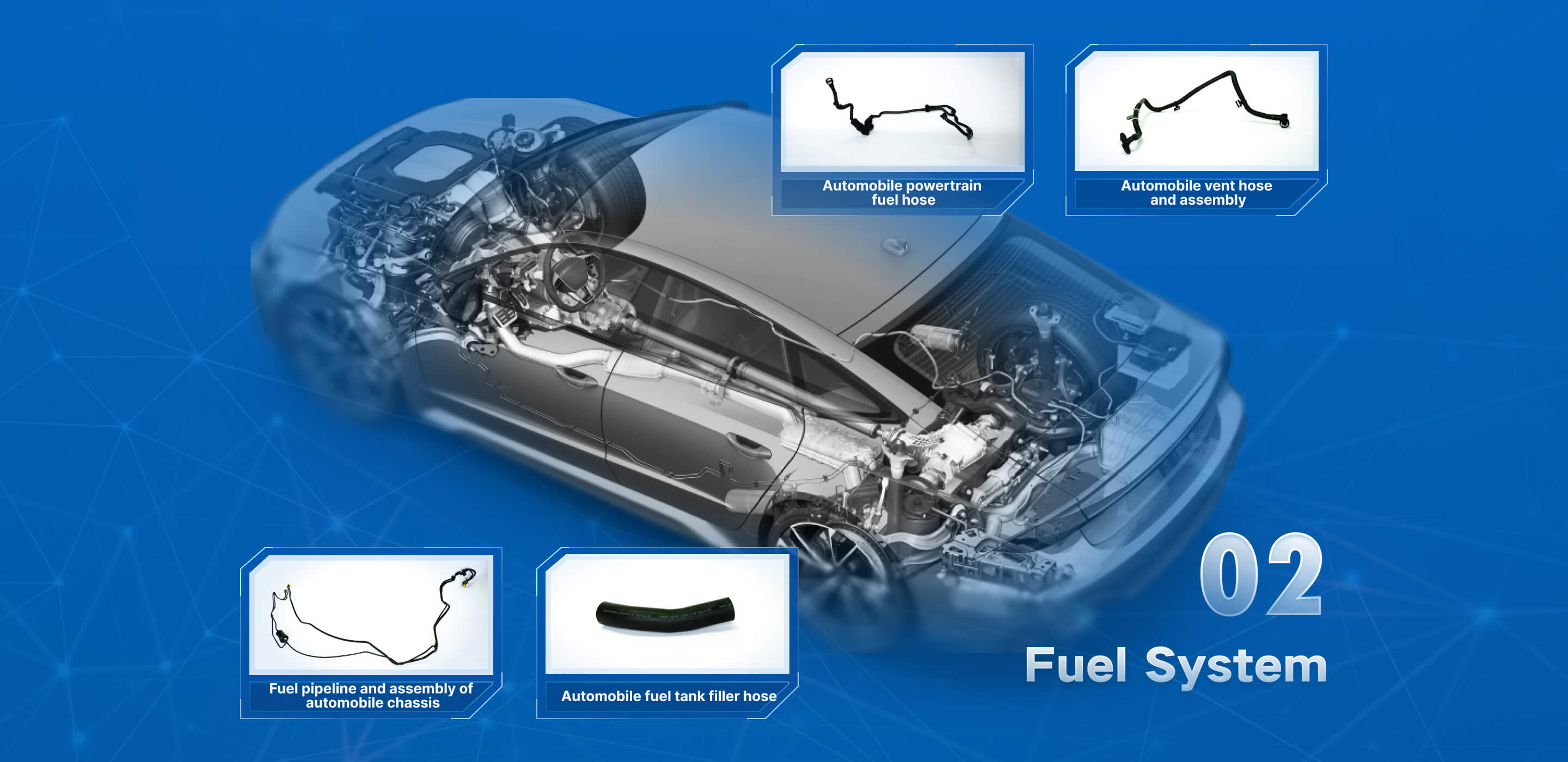

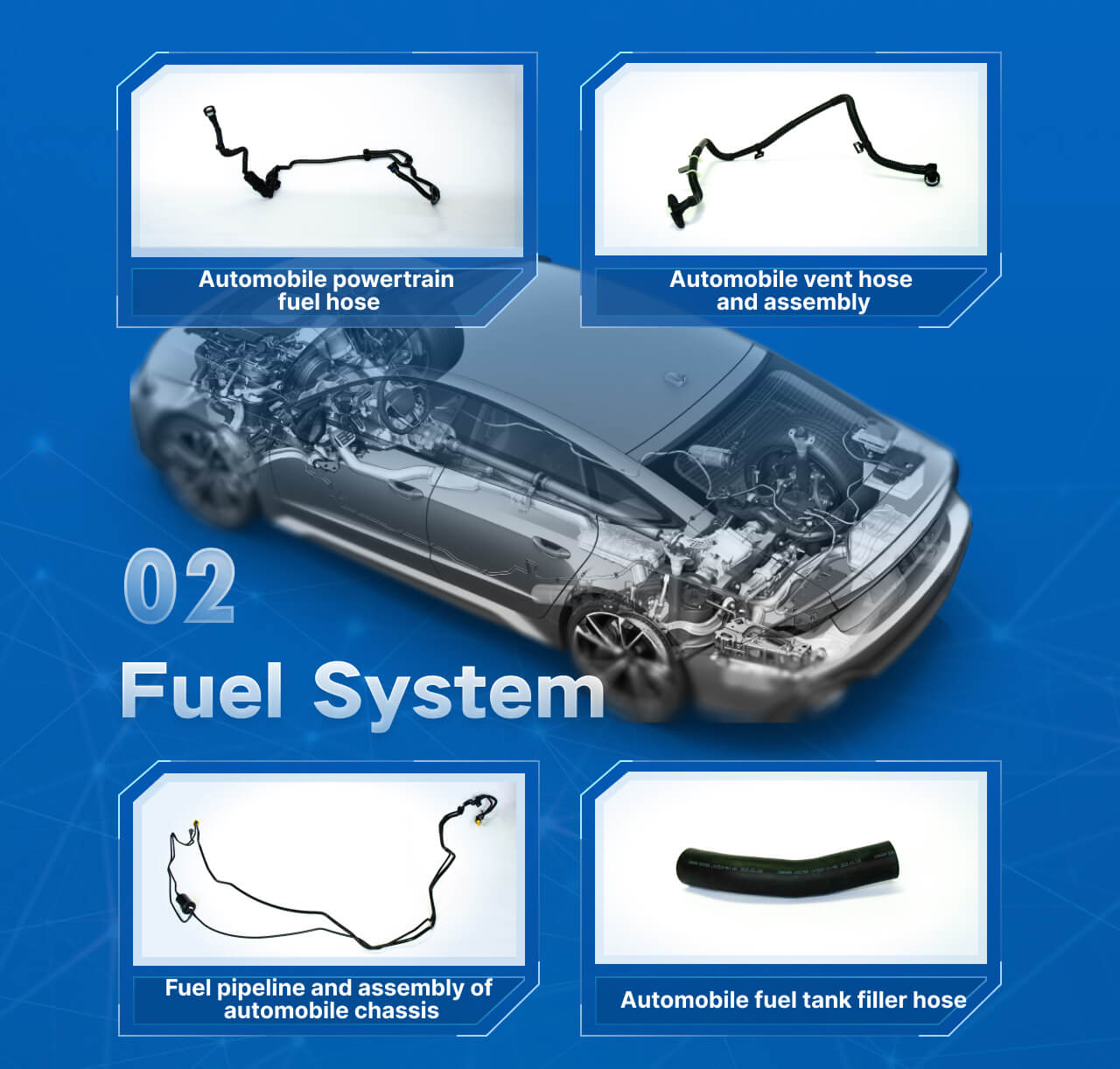

Product classification includes: powertrain fuel pipeline, chassis fuel pipeline, refueling pipeline, and vent pipeline. It is used in automobile fuel system to connect engine, oil pump, fuel tank, carbon canister and other main parts, convey fuel or fuel vapor, and realize medium circulation.

The fuel hose of the power assembly has a double barrier layer of fluororubber and fluororesin, which has extremely low permeability of fuel medium. The pipe has conductive characteristics, effectively avoiding the risk of spontaneous combustion of vehicles caused by static charges caused by fuel flowing through, and ensuring life safety.

The refueling hose can choose THV or CPT as the permeation barrier to meet the requirements of the "China VI" and "China VII" laws and regulations. At the same time, the unique integrated coreless production process can avoid the process risk of segmented and cored extrusion to the maximum extent, and effectively ensure the product quality.

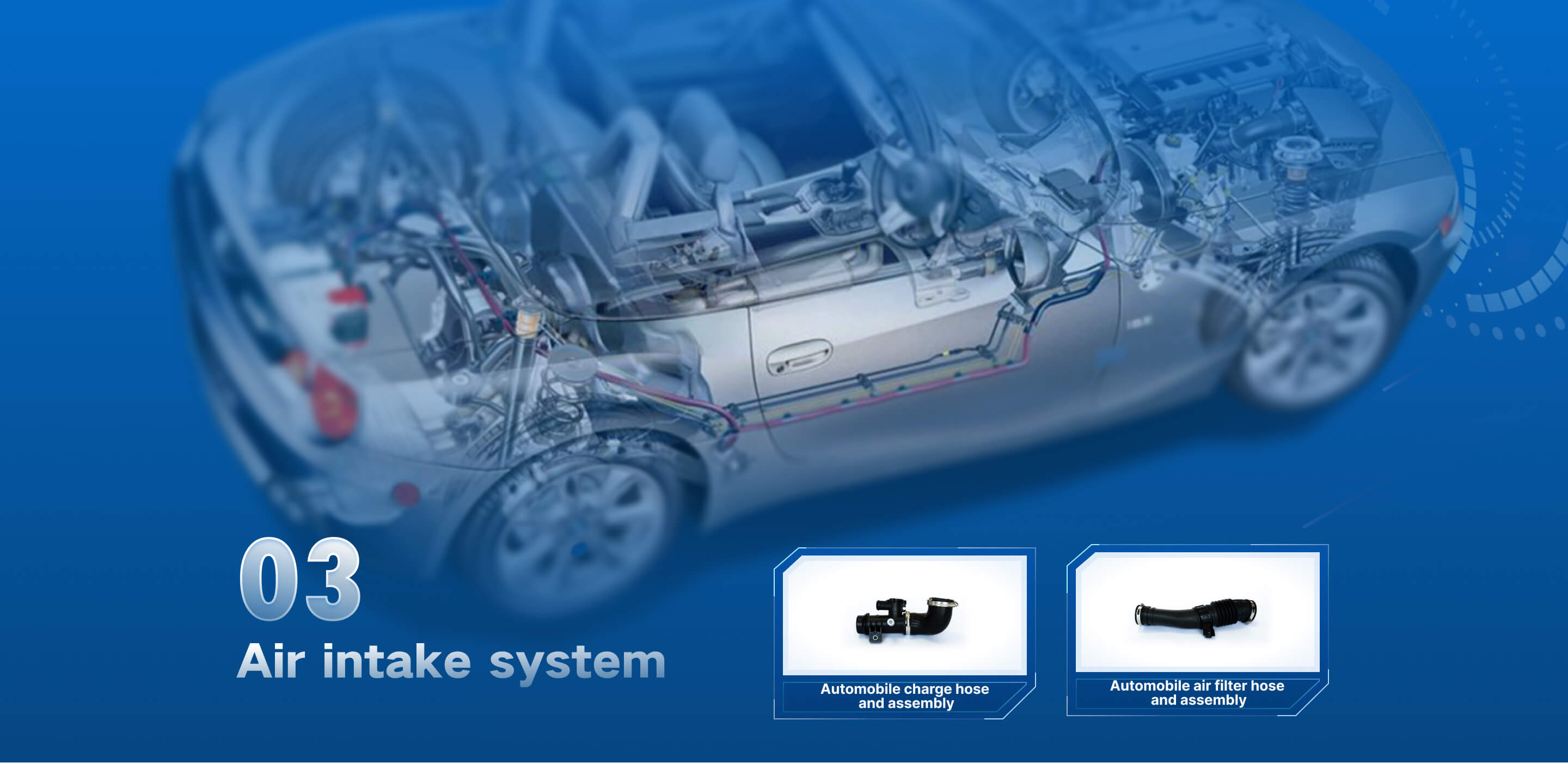

Product classification includes: charge hose, intercooler outlet hose, air filter hose, etc. in traditional fuel vehicles, intercooling hose in hydrogen fuel cell vehicles, etc. It is used in the air intake system of automobile engines to connect the turbocharger, intercooler, intake manifold and other major components, and to transfer the hot air charged by the turbocharger to the intercooler for cooling and then to the intake manifold, so as to provide sufficient air for engine combustion and increase the combustion efficiency.

The charge hose and assembly are used to reduce the temperature of high-temperature air after pressurization, reduce the thermal load of the engine, increase the intake air volume, and then increase the power of the engine. The materials are rich, covering the working conditions of - 50℃ to 260℃. At the same time, they can meet the special acid resistance requirements of the new emission regulations in traditional fuel vehicles, ensure a wider application range of the pipeline in the whole vehicle, and provide a stable power operation scheme for the whole vehicle;

The air filter hose and assembly, including the air inlet and outlet hoses of the air filter, are made of lightweight plastic solutions, equipped with advanced automation equipment, stable process parameters and full process monitoring capabilities, and have good product quality assurance.

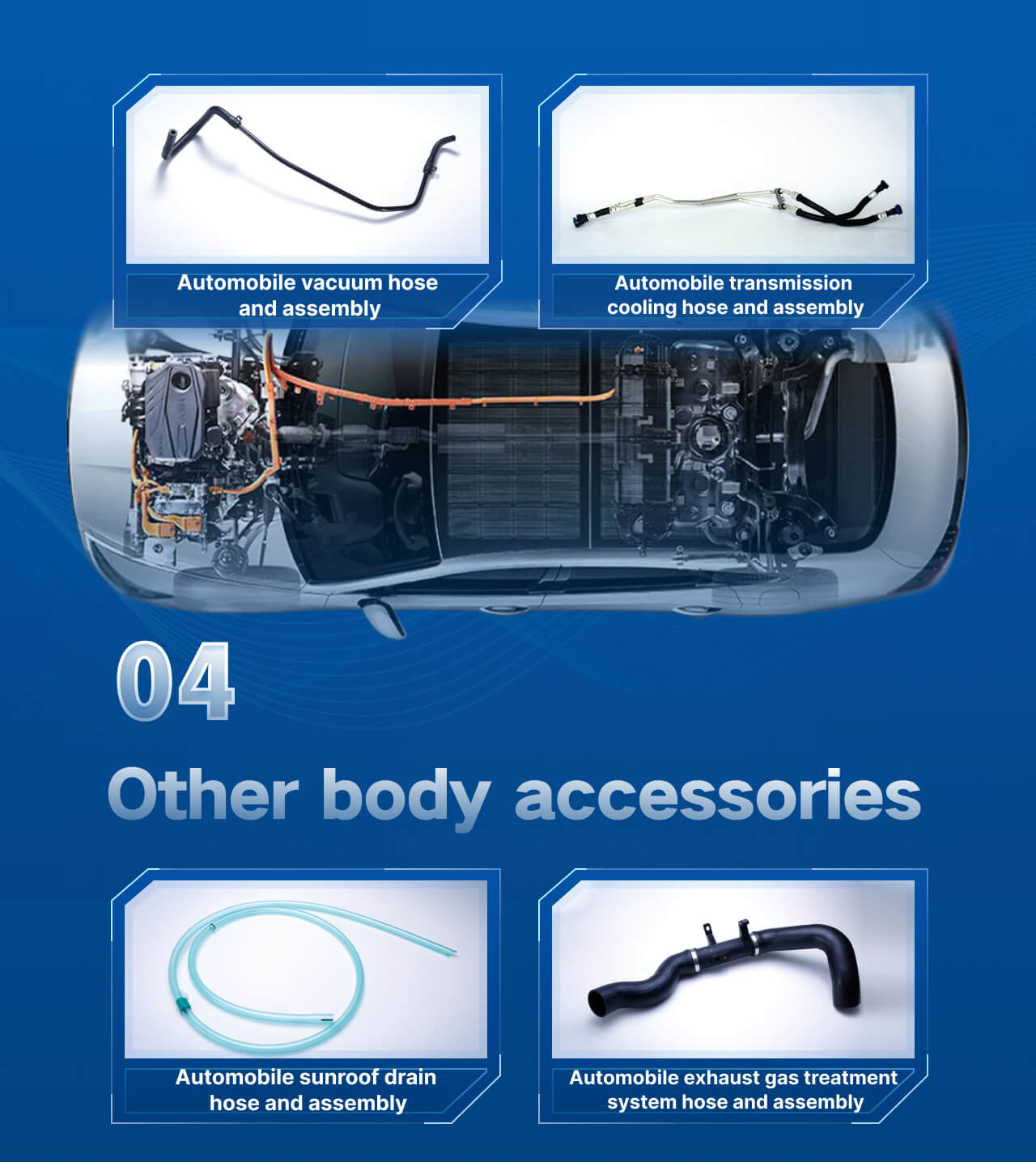

The classification includes transmission oil cooling pipeline assembly, skylight drainage system pipeline and assembly, automobile vacuum brake pipeline and assembly, and automobile exhaust gas treatment system pipeline and assembly.

The oil cooling pipeline connects the gearbox and radiator to deliver the gearbox oil and realize the gearbox heat dissipation.

The sunroof drainage system hose is connected with the sunroof drainage channel and the chassis plate reinforcement to guide the water in the sunroof drainage channel to the ground.

The vacuum brake hose connects the engine air intake system and the vacuum booster. It transfers the negative pressure from the air intake system to the vacuum booster to increase the braking force. At the same time, it regulates the negative pressure of the engine under various working conditions.

The hose of automobile exhaust gas treatment system includes GPF, low pressure EGR and other hoses. According to customer requirements, it can match the requirements of -40℃ ~ 250℃full temperature grade, and at the same time, it has excellent resistance to engine exhaust acid medium, providing pipeline solutions for exhaust gas treatment system under all working conditions.

- +86-22-63269287

- +86-22-63269748

-

WeChat Official Account

WeChat Official Account

- Fluid pipeline series

- Thermal management system

- Fuel system

- Air intake system

- Other body accessories

- Sealing parts series

- European series

- Japanese and Korean series

- Frameless

- Zero order difference

- Human resources

- Talent strategy

- Campus recruitment

- Social recruitment

- Recruitment guidelines

- Contact us

- Contact us

- Enterprise map

Copyright © 2021 www.pengling.cn All Rights Reserved.

天津鹏翎集团股份有限公司

津ICP备14007122号-1